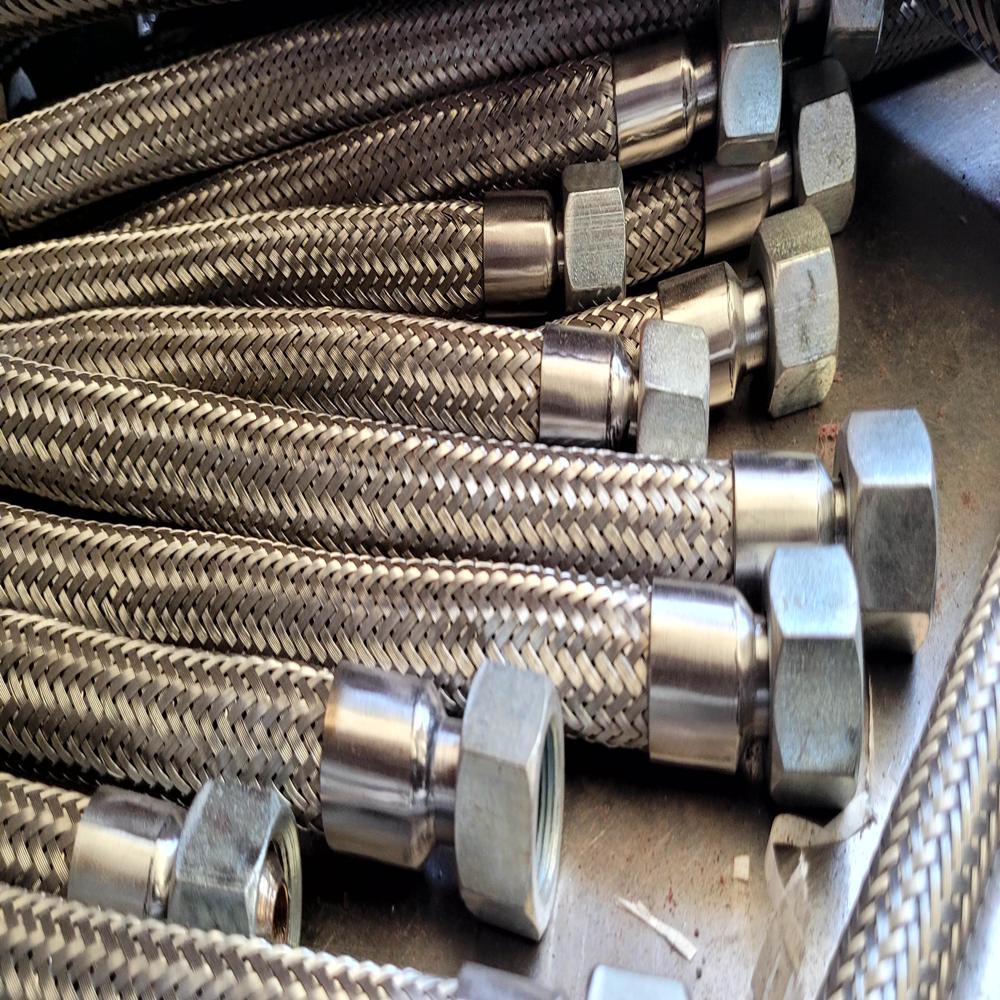

CORRUGATED STAINLESS STEEL HOSES

Price 540.0 INR/ Piece

CORRUGATED STAINLESS STEEL HOSES Specification

- Connection Type

- Flanged, Threaded, or Welded

- Reinforcement

- Stainless steel wire braid

- Hardness

- As per ASTM A240 / AISI grade

- Cover

- Stainless steel

- Medium

- Liquids, Gases, Steam, Chemicals

- Shape

- Corrugated hose

- Material

- Stainless Steel (Grades 304, 316, 321)

- Temperature

- -200C to +600C

- Pressure

- Up to 300 bar

- Inside Diameter

- 6 mm to 300 mm

- Outside Diameter

- Variable as per design

- Corrugation Type

- Annular or Helical

- Burst Pressure

- 3 times working pressure

- Leak Test

- Hydrostatic & Pneumatic

- Color

- Metallic silver

- Standards

- ISO 10380, BS 6501

- End Fittings

- SS, Brass, or as specified

- Bending Radius

- Minimum standard as per DIN EN ISO 10380

- Working Length

- Custom as per requirements

- Application

- Flexible connections for vibration, piping offset, and thermal expansion

CORRUGATED STAINLESS STEEL HOSES Trade Information

- Minimum Order Quantity

- 1000 Pieces

- FOB Port

- NEW DELHI

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 500 Pieces Per Day

- Delivery Time

- 7 Days

- Sample Available

- No

- Sample Policy

- Free samples are available

- Packaging Details

- BUBBLE WRAP

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO

About CORRUGATED STAINLESS STEEL HOSES

Product Specification SS Corrugated Flexible Hoses

Material Options:

-

Stainless Steel SS 304 / SS 316 / SS 321

Construction:

-

Inner Hose: Annularly corrugated stainless steel tube (for maximum flexibility)

-

Outer Braid: High tensile stainless steel wire (for pressure reinforcement, optional single or double braid)

-

End Fittings: Flanged / Threaded / Welded / Customized as per requirement

Size Range:

-

Nominal Bore (NB): 6 mm to 300 mm ( to 12)

-

Custom sizes available on request

Pressure Rating:

-

Up to 350 Bar (varies with size & braid type)

Temperature Range:

-

-196C to +700C (depending on grade of stainless steel)

Bend Radius:

-

As per DIN/BS standards (varies with hose size)

Applications:

-

Oil & Gas Pipelines

-

Chemical & Petrochemical Plants

-

Steam & Hot Water Lines

-

Automotive Exhaust Systems

-

HVAC & Refrigeration

-

Power Plants

-

Food & Pharmaceutical Industry

Features:

-

High flexibility with annular corrugations

-

Leak-proof and pressure resistant

-

Excellent resistance to vibration, thermal expansion, and corrosion

-

Available in single / double braid for higher strength.

Customizable for Versatile Applications

Whether for absorbing vibration, accommodating pipe offset, or thermal expansion, these corrugated stainless steel hoses can be tailored in length, diameter, and end fittings. Reinforced with stainless steel wire braid for added strength, they adapt to applications in liquids, gases, steam, and chemicals, making them a flexible solution for numerous industries.

Engineered to International Standards

Our hoses are designed and manufactured according to stringent standards, including ISO 10380 and BS 6501. Each unit is tested for leaks under both hydrostatic and pneumatic conditions to guarantee safe, reliable performance-even at burst pressures up to three times the working pressure.

Flexible Connections with Reliable Durability

Blending high-quality stainless steel construction with a corrugated design and metallic silver finish, these hoses excel in challenging temperature and pressure environments. The precise combination of materials and structural details ensures a long service life for connections where dependability is paramount.

FAQ's of CORRUGATED STAINLESS STEEL HOSES:

Q: How are corrugated stainless steel hoses used in industrial applications?

A: Corrugated stainless steel hoses are commonly installed to provide flexible connections where vibration absorption, piping offset, or thermal expansion exists, such as in piping, steam lines, or chemical transfer systems. Their flexibility and strength enable reliable operation across various industries.Q: What corrugation types can I choose from for these hoses?

A: You can select between annular (circular rings) or helical (spiral-shaped) corrugations, depending on your pressure, flexibility, and installation requirements. Both types are designed per ISO 10380 for optimum performance.Q: When should I specify custom working lengths for my hose?

A: Custom working lengths are ideal when you have unique installation constraints or specific distance requirements between connection points. Providing accurate measurements ensures the hose fits seamlessly into your system for optimal reliability.Q: Where are these hoses typically installed?

A: These hoses are widely used in industrial environments throughout India and globally, including chemical plants, power generation facilities, refineries, and HVAC systems-anywhere flexible, corrosion-resistant piping is necessary.Q: What process is followed for testing hose integrity?

A: Each hose undergoes both hydrostatic and pneumatic leak testing as per international standards. This rigorous process ensures the hose maintains its integrity under pressure and can handle burst conditions three times the working pressure.Q: What are the benefits of stainless steel wire braiding on these hoses?

A: The stainless steel wire braid reinforcement significantly increases pressure handling capability, maintains hose shape, and adds protection against mechanical damage, enhancing the hose's overall durability and safety.Q: Can the hoses accommodate different connection types and materials?

A: Yes, end fittings are customizable and available in stainless steel, brass, or other specified materials, with options for flanged, threaded, or welded connections to ensure compatibility with your piping system.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hose Pipe Category

Chemical Transfer Corrugated Hose

Price 780.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Other, Synthetic Rubber

Temperature : 40C to +120C

Outside Diameter : 33 mm

Shape : Corrugated

SS HOSE ASSEMBLY

Price 350.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Material : Other, Stainless Steel 304/316

Temperature : 196C to 600C

Outside Diameter : Varies as per size and construction

Shape : Flexible round hose

Flexible Braided Hose for Industry

Price 1220.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Material : Metal

Temperature : 200 C to +600 CV Celsius (oC)

SS BRAIDED FLEXIBLE HOSE

Price 540.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Metal

Temperature : 200 C to +600 C (depending on SS grade). Celsius (oC)

Outside Diameter : 300 mm (12 ) Meter (m)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS