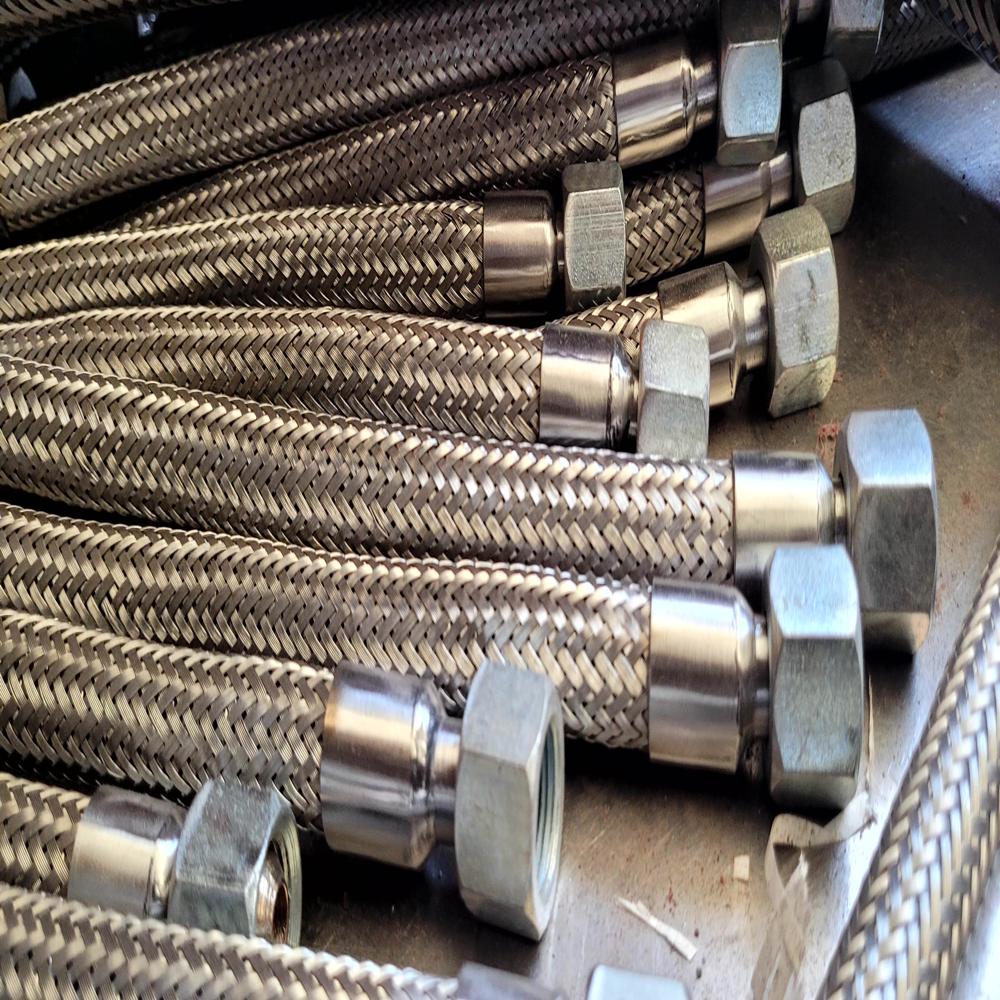

SS HOSE ASSEMBLY

Price 350.0 INR/ Piece

SS HOSE ASSEMBLY Specification

- Reinforcement

- Single or double SS304/SS316 braided

- Shape

- Flexible round hose

- Hardness

- Flexible (as per SS flexible hose properties)

- Connection Type

- Flanged, Threaded, Quick-Connect, Camlock, or as specified

- Medium

- Suitable for air, gas, water, steam, oil, chemicals

- Cover

- Stainless Steel Wire Braid

- Material

- Stainless Steel 304/316

- Temperature

- -196C to 600C

- Pressure

- Up to 300 Bar

- Inside Diameter

- 6 mm to 300 mm

- Outside Diameter

- Varies as per size and construction

- Application

- Industries including refineries, chemical, pharma, food, and engineering

- Inner Hose Thickness

- Range 0.18 mm to 1.0 mm

- Leak Test

- 100% hydrostatic and pneumatic tested

- Corrugation

- Annular (standard), helical possible

- Color

- Metallic silver (natural SS finish)

- Vibration Resistance

- Excellent for absorbing vibration and thermal expansion

- End Fitting Material

- Stainless Steel, Brass, or as specified

- Length

- Custom, as per order (typically up to 20 meters in single length)

- Burst Pressure

- 3 times working pressure minimum

- Bend Radius

- Dependent on hose diameter and construction, typically very flexible

SS HOSE ASSEMBLY Trade Information

- Minimum Order Quantity

- 50 Pieces

- FOB Port

- NEW DELHI

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 7 Days

- Sample Available

- No

- Sample Policy

- Free samples are available

- Packaging Details

- BUBBLE WRAP

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO

About SS HOSE ASSEMBLY

SS Flexible Hoses are specially designed to handle high pressure, extreme temperatures, and corrosive environments. Manufactured from high-grade stainless steel, these hoses offer excellent flexibility, strength, and long service life, making them ideal for industrial, commercial, and automotive applications.

They are available in corrugated (for flexibility) and braided (for pressure reinforcement) types, ensuring leak-proof performance even under tough operating conditions.

Key Features:

-

Made from premium stainless steel (SS 304/316/321)

-

High pressure resistance with SS wire braiding

-

Withstands high & low temperatures

-

Excellent corrosion resistance

-

Flexible yet strong absorbs vibration & thermal expansion

-

Available in various sizes, lengths, and end fittings

Applications:

-

Oil & Gas Industry

-

Chemical Plants

-

Power Generation

-

Automotive Exhaust Systems

-

Steam & Hot Water Lines

-

HVAC & Plumbing

-

Food & Pharmaceutical Industry

Flexible by Design, Dependable in Action

Engineered with corrugated stainless steel and flexible construction, our SS Hose Assemblies excel at absorbing vibrations and handling thermal expansion. Their robust design ensures a minimal bend radius, making them ideal for space-constrained or dynamic environments without compromising structural integrity.

Customizable to Match Your Requirements

We offer a range of sizes, from 6 mm to 300 mm inside diameter, with custom lengths up to 20 meters per assembly. End fittings can be chosen from flanged, threaded, quick-connect, camlock, or tailored to your specifications, making these hoses suitable for an array of industrial applications.

Built for Safety and High Performance

Every hose assembly undergoes rigorous 100% hydrostatic and pneumatic leak testing. Designed to withstand temperatures from -196C up to 600C, and a burst pressure at least three times the working pressure, these hoses ensure safe, reliable operation in even the most demanding processes.

FAQ's of SS HOSE ASSEMBLY:

Q: How are SS Hose Assemblies usually installed and connected to existing systems?

A: SS Hose Assemblies are installed by securing the correct end fittings-flanged, threaded, quick-connect, camlock, or custom-to the corresponding connectors on your system. It is important to select the appropriate fitting material and type, and follow recommended torque specifications to guarantee a leak-free and secure installation.Q: What factors determine the right hose construction and size for my application?

A: Selection should be based on the medium being conveyed (air, gas, water, chemicals, etc.), required pressure rating (up to 300 Bar), temperature range (-196C to 600C), desired flexibility, vibration levels, and available installation space. The inside diameter (6 mm to 300 mm) and hose length (custom, up to 20 meters) are chosen to match system requirements.Q: When is single or double SS wire braiding recommended?

A: Single SS wire braid is suitable for most moderate pressure and general vibration applications. Double braiding is recommended for higher pressure systems, increased vibration, and where added strength and kink resistance are critical. Selection is typically based on system pressure, flexibility, and safety needs.Q: Where are these SS Hose Assemblies typically utilized?

A: Our hoses find widespread application in refineries, chemical and pharmaceutical processing, food industry, and various engineering sectors. They are ideal wherever flexible, corrosion-resistant solutions for transferring air, steam, water, oil, or chemicals are required, especially when vibration absorption and high-pressure capabilities are needed.Q: What testing processes do these hose assemblies undergo?

A: Each assembly is subjected to 100% hydrostatic and pneumatic testing before delivery. This ensures there are no leaks, verifying structural integrity and confirming that the hose assembly meets or exceeds its specified burst and working pressures.Q: How do I ensure proper usage and longevity of the hose assembly in harsh conditions?

A: Regular inspection for signs of wear or deformation, proper installation to avoid twisting or over-bending, and adherence to specified bend radius and pressure ratings are essential. Choosing the right hose thickness and reinforcement level for your application's environment will maximize service life and performance.Q: What are the key benefits of using SS Hose Assemblies in industrial systems?

A: The main advantages include superior corrosion resistance, high flexibility, excellent vibration and thermal expansion absorption, capability to handle extreme pressures and temperatures, compatibility with various media, and ease of customization with multiple end fittings-all delivered with reliable, factory-tested performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hose Pipe Category

CORRUGATED STAINLESS STEEL HOSES

Price 540.0 INR / Piece

Minimum Order Quantity : 1000 Pieces

Material : Other, Stainless Steel (Grades 304, 316, 321)

Shape : Corrugated hose

SS BRAIDED FLEXIBLE HOSE

Price 540.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Metal

Color : SILVER

Size : 0.6" 14"

Annular corrugated hose

Price 670.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Metal

Shape : Round

Color : Silver

Size : 6 mm to 300 mm ( to 12)

Oxygen Hose Pipe

Price 750.0 INR / Meter

Minimum Order Quantity : 10 Pieces

Material : Other

Shape : Round

Color : Silver

Size : 1/4 inch 12 inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS