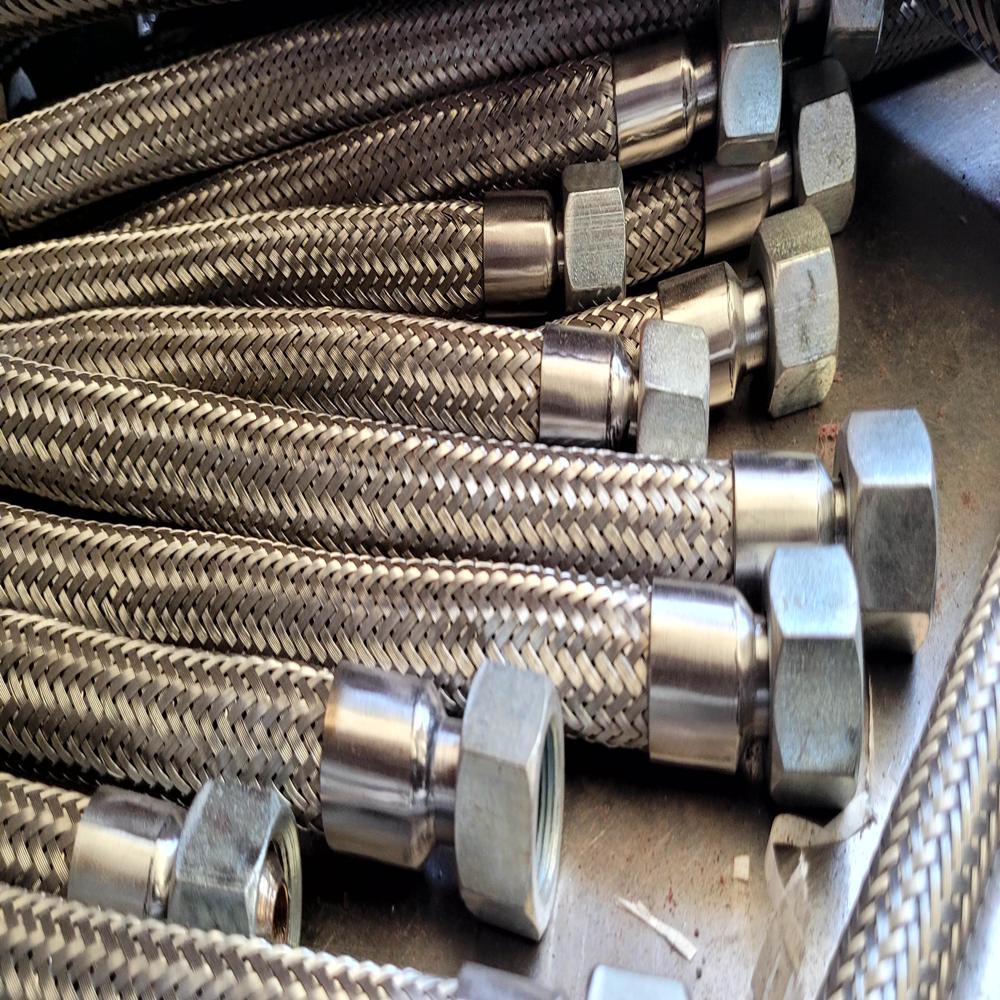

Chemical Transfer Corrugated Hose

Price 780.0 INR/ Piece

Chemical Transfer Corrugated Hose Specification

- Hardness

- Shore A 705

- Reinforcement

- High tensile synthetic yarn with steel wire helix

- Shape

- Corrugated

- Cover

- Abrasion and chemical resistant rubber

- Medium

- Acids, alkalis, chemicals

- Connection Type

- Flanged/Threaded

- Material

- Synthetic Rubber

- Temperature

- -40C to +120C

- Pressure

- 10 bar

- Inside Diameter

- 25 mm

- Outside Diameter

- 33 mm

- Weight per meter

- 0.9 kg

- End Fitting Material

- Carbon steel/Stainless steel

- Manufacturing Method

- Extruded and vulcanized

- UV Resistance

- Yes

- Application

- Transfer of aggressive chemicals in process industries

- Compliance Standard

- IS 7654:1975

- Burst Pressure

- 30 bar

- Color

- Black/Grey

- Ozone Resistance

- Yes

- Bend Radius

- 150 mm

- Length

- Up to 20 meters

- Vacuum Resistance

- 600 mm Hg

Chemical Transfer Corrugated Hose Trade Information

- Minimum Order Quantity

- 100 Pieces

- FOB Port

- NEW DELHI

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 7 Days

- Sample Available

- No

- Sample Policy

- Free samples are available

- Packaging Details

- BUBBLE WRAP

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO

About Chemical Transfer Corrugated Hose

SS Corrugated Hoses are engineered for applications that demand high flexibility, strength, and durability under extreme working conditions. Manufactured from premium grades of stainless steel (SS 304, SS 316, SS 321), these hoses are designed with annular corrugations that provide excellent flexibility and allow them to absorb vibration, thermal expansion, and contraction effectively.

For additional strength, the hoses are reinforced with a single or double stainless steel wire braid, ensuring reliable performance under high pressure and temperature variations.

Durability and Safety Assurance

Built with extruded and vulcanized synthetic rubber, this hose delivers superior resistance to abrasion, chemicals, UV, and ozone. Reinforced with high tensile yarn and steel wire helix, it ensures reliable performance even under demanding industrial conditions.

Versatile Applications in Process Industries

With a bend radius of 150 mm and vacuum resistance up to 600 mm Hg, this hose is tailored for the transfer of acids, alkalis, and other aggressive chemicals. It supports a range of chemical media, enabling safe operations in a variety of industrial environments.

FAQ's of Chemical Transfer Corrugated Hose:

Q: How is the Chemical Transfer Corrugated Hose installed in process industries?

A: The hose is installed using flanged or threaded end fittings, made from carbon steel or stainless steel, to ensure a robust and secure connection to process equipment. Its flexible, corrugated design allows for easy routing and adaptability within facility layouts.Q: What chemicals can this hose safely transfer?

A: This hose is engineered to handle a wide array of aggressive chemicals, including acids, alkalis, and various industrial chemical compounds, thanks to its synthetic rubber construction and specialized chemical-resistant cover.Q: When is it appropriate to use this hose for chemical transfer?

A: The hose is suitable for use whenever safe, reliable transfer of corrosive or aggressive chemicals is required, especially in environments where resistance to UV, ozone, and abrasion is crucial. It operates efficiently within a temperature range of -40C to +120C.Q: Where is this hose commonly used within the chemical process industry?

A: It is commonly employed in chemical manufacturing plants, pharmaceutical facilities, petrochemical sites, and other industrial settings where the secure movement of hazardous or reactive chemicals is essential.Q: What is the manufacturing process for this hose?

A: This hose is produced through a meticulous process involving extrusion and vulcanization of synthetic rubber, reinforcing it with high tensile yarn and a steel wire helix. The result is a robust, flexible, and chemically resistant hose structure.Q: How does the hose's design benefit chemical handling operations?

A: The corrugated shape offers enhanced flexibility, while the robust reinforcement ensures high burst pressure capability and vacuum resistance. These design features reduce risk of failure during chemical transfer, improving operational safety and efficiency.Q: What standards does this hose comply with, and why is that important?

A: It complies with IS 7654:1975 standards, which establishes requirements for safety, reliability, and performance in chemical transfer hoses. Compliance ensures users receive a product capable of meeting stringent industrial quality and safety criteria.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hose Pipe Category

CORRUGATED STAINLESS STEEL HOSES

Price 540.0 INR / Piece

Minimum Order Quantity : 1000 Pieces

Material : Other, Stainless Steel (Grades 304, 316, 321)

Shape : Corrugated hose

Pressure : Up to 300 bar

Industrial Flexible Hose

Price 250.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Material : Other, Industrial grade synthetic rubber

Shape : Round

Pressure : up to 10 bar

SS BRAIDED FLEXIBLE HOSE

Price 540.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Metal

Size : 0.6" 14"

Pressure : up to 150 bar Bar

Flexible Braided Hose for Industry

Price 1220.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Material : Metal

Size : NB 6 mm ( ) to 300 mm (12 )

Pressure : 150 Bar

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free