High Temperature Braided Hose

Price 1230.0 INR/ Piece

High Temperature Braided Hose Specification

- Medium

- Hot Air, Steam, Chemicals

- Shape

- Round

- Hardness

- Shore A 70 5

- Reinforcement

- Stainless Steel Wire Braided

- Connection Type

- Flanged, Threaded

- Cover

- High Temperature Silicone

- Material

- Silicone Rubber

- Temperature

- -70C to +260C

- Pressure

- Up to 40 bar

- Inside Diameter

- 10 mm to 50 mm

- Outside Diameter

- 12 mm to 54 mm

- Standards

- Compliant with ISO 10380

- Fire Resistance

- High

- Flexibility

- Excellent

- UV Resistance

- Excellent

- Application

- Furnace, Foundry, Chemical Transfer, High Temp Processing

- Color

- Red, Black, or as required

- Length

- Available in custom lengths up to 20 meters

- Bursting Pressure

- Up to 120 bar

- Manufacturing Technique

- Extruded and Braided

- Inner Tube

- Smooth silicone rubber

High Temperature Braided Hose Trade Information

- Minimum Order Quantity

- 50 Pieces

- FOB Port

- NEW DELHI

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 200 Pieces Per Week

- Delivery Time

- 7 Days

- Sample Available

- No

- Sample Policy

- Free samples are available

- Packaging Details

- BUBBLE WRAP

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO

About High Temperature Braided Hose

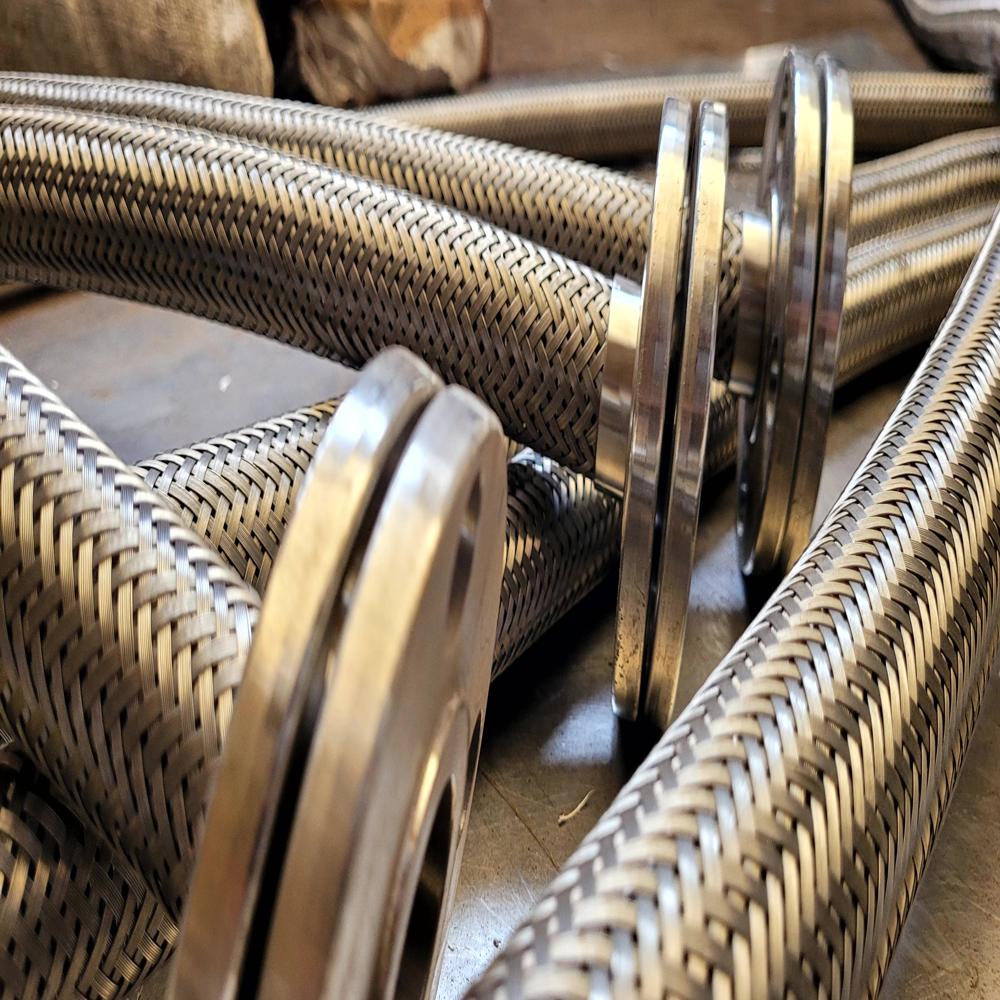

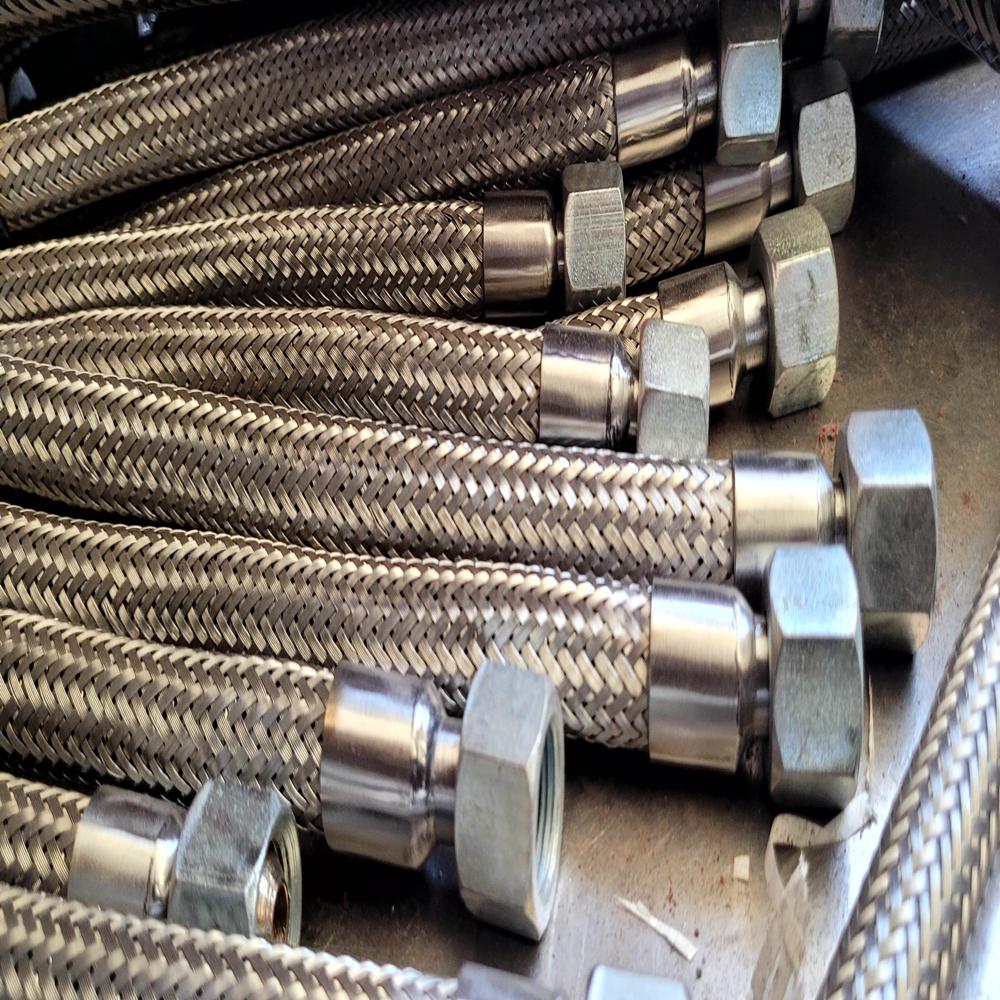

SS Braided Flexible Hoses High Strength & Leak-Proof Performance

SS Braided Hoses are designed for applications that require flexibility, durability, and resistance to high pressure. These hoses consist of an inner corrugated stainless steel tube that provides flexibility, reinforced with a stainless steel wire braid that enhances pressure resistance and prevents elongation under pressure.

Made from high-quality SS 304, SS 316, or SS 321, they offer excellent corrosion resistance, thermal stability, and mechanical strength, making them ideal for demanding industrial and commercial environments.

Key Benefits:

-

Withstands high pressure & vacuum conditions

-

Excellent corrosion & chemical resistance

-

Leak-proof design with reinforced braiding

-

Absorbs vibrations & thermal expansion

-

Available in single and double braid construction

-

Compatible with a wide range of end fittings (flanged, threaded, welded)

Applications:

-

Oil & Gas Pipelines

-

Petrochemical & Chemical Industry

-

Power Plants & Boilers

-

Automotive Exhaust Systems

-

Steam & Hot Water Lines

-

Hydraulic & Pneumatic Systems

-

Food & Pharmaceutical Industry

-

HVAC & Refrigeration Systems

Superior Material and Design

Manufactured using high-quality silicone rubber and reinforced with stainless steel wire, this hose guarantees longevity and reliability in demanding environments. Its extruded and braided construction enhances both flexibility and fire resistance, ensuring optimal performance in various industrial sectors.

Engineered for Extreme Conditions

Engineered to handle temperatures ranging from -70C to +260C and pressures up to 40 bar, this hose supports applications that demand resilience against corrosion, heat, and UV exposure. It is perfectly suited for use in furnaces, foundries, chemical processing, and high-temperature transfer operations.

Tailored to Fit Your Needs

Available in custom lengths up to 20 meters and diameters from 10 mm to 50 mm, the hose meets diverse industrial requirements. Connection types include flanged and threaded options to ensure compatibility with your system.

FAQ's of High Temperature Braided Hose:

Q: How should the High Temperature Braided Hose be installed for optimal performance?

A: For best results, the hose should be securely fitted using compatible flanged or threaded connectors, ensuring that the installation does not expose the hose to kinking or excessive bending. Adhere to ISO 10380 guidelines and keep within specified pressure and temperature limits.Q: What makes this hose suitable for extreme temperature and pressure applications?

A: The combination of a smooth silicone rubber inner tube and stainless steel wire reinforcement allows the hose to operate from -70C to +260C and withstand pressures up to 40 bar, with a bursting pressure up to 120 bar. This makes it reliable for transferring hot air, steam, and chemicals in harsh settings.Q: When is it necessary to replace the braided hose?

A: Inspect the hose regularly for any signs of wear such as cracks, abrasions, or reduced flexibility. Replacement is recommended if there are visible damages, compromised fittings, or if the hose is subjected to pressures or temperatures beyond specified limits.Q: Where can this hose be used most effectively?

A: This hose is ideal for furnace and foundry operations, chemical transfer, high-temperature processing, and any industry where resistance to heat, flames, and chemicals is critical. Its robust construction ensures safe operation in demanding industrial environments.Q: What are the key benefits of using a stainless-steel wire-braided silicone hose?

A: The stainless-steel braiding enhances pressure resistance while the silicone provides excellent flexibility, high fire and UV resistance, and longevity. This combination ensures consistent performance and reduced maintenance in harsh industrial environments.Q: How does the manufacturing process enhance hose durability?

A: Our hose is extruded and then braided, which provides a smooth interior for better flow and external reinforcement for longevity. This process results in a hose that can withstand continuous mechanical stress and extreme temperatures effectively.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hose Pipe Category

SS BRAIDED FLEXIBLE HOSE

Price 540.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Size : 0.6" 14"

Material : Metal

Color : SILVER

Annular corrugated hose

Price 670.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Size : 6 mm to 300 mm ( to 12)

Material : Metal

Color : Silver

Shape : Round

Oxygen Hose Pipe

Price 750.0 INR / Meter

Minimum Order Quantity : 10 Pieces

Size : 1/4 inch 12 inch

Material : Other

Color : Silver

Shape : Round

Oxygen Gas Hose

Price 340.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Size : 1 inch

Material : Other

Color : Silver

Shape : Round

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS